Learn the factors to consider when choosing the best material handling equipment to fit your warehouse layout and needs, from hand trucks to mobile robots.

Undoubtedly, e-commerce has exploded recently, leaving the supply chain struggling to keep up with the increased demand. As a result, warehousing and distribution centers have become more important than ever as vast amounts of goods are stored, inventoried, packed, and shipped worldwide.

However, not every warehouse is a shipping hub, and many materials require specialized care leaving no one-size-fits-all solution for bulk material handling equipment. This article explores solutions for different Warehouse Management Systems (WMS) to ensure proper material handling.

Inventory Management and Storage

Before a decision can be made on the optimization of warehouse storage equipment, some factors must be considered:

Warehouse Layout and Business Needs

The space utilization of a warehouse is crucial to determining the material handling equipment. Confined warehouse space with narrow aisles and limited floor space will favor maneuverability. A facility moving materials from large silos through hoppers, conveyor belts, or even grain elevators would require heavier-duty equipment. An order fulfillment facility may only be able to meet demand using automatic guided vehicles.

Your Unit Load

A load you can store or move as a single entity is called a unit load. This can include a container, tote, or pallet. Knowing the size, shape, and weight of a typical unit load is critical in determining the types of material handling equipment required.

Types of Material Handling Equipment

Hand-Operated

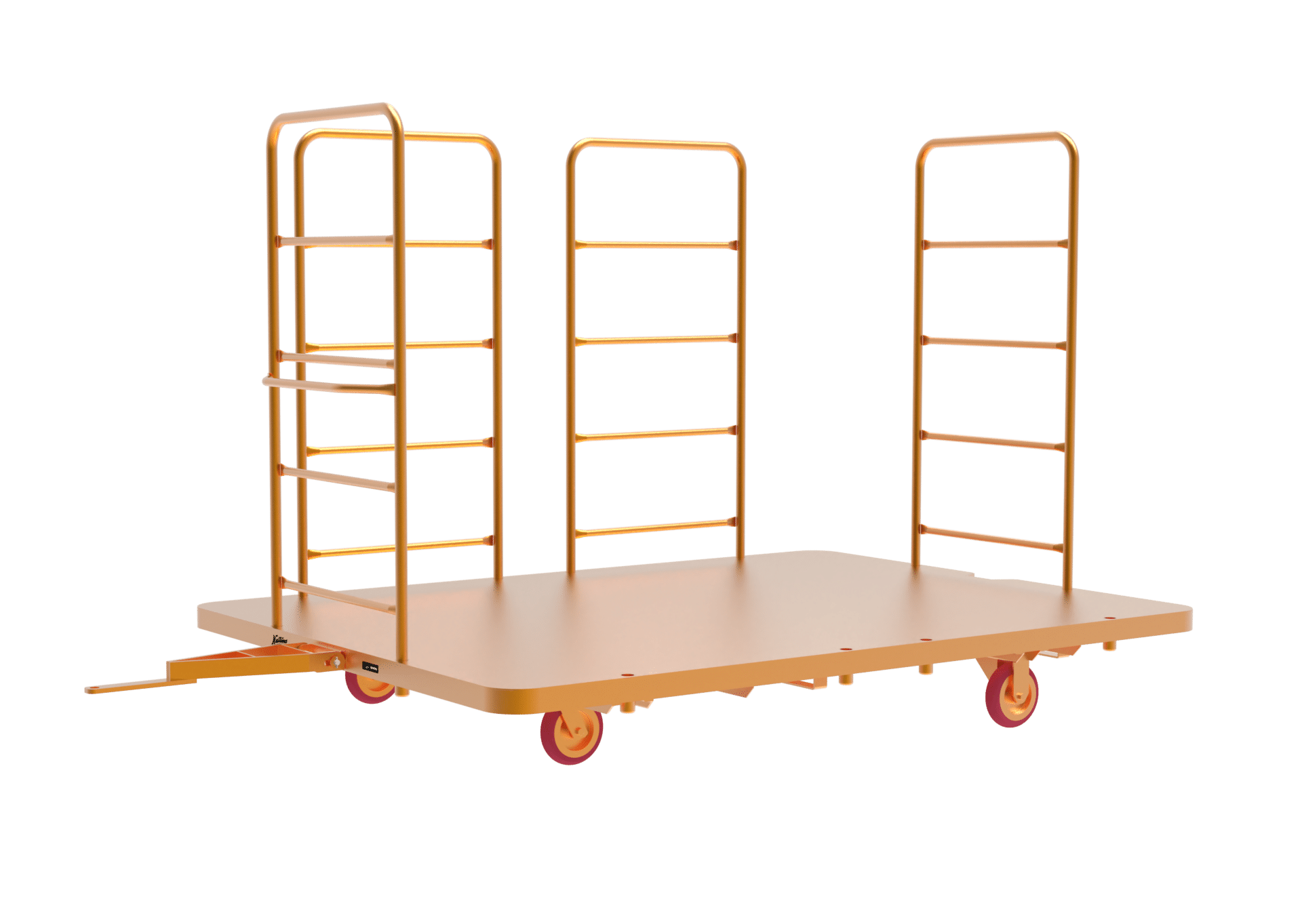

Hand-operated carts, like hand trucks, dollies, pallet jacks, and A-Frame carts, offer increased mobility in tight spaces, more accessible transportation of goods, and reduced manual labor. All of which leads to increased efficiency. Most hand-operated material handlers are designed to be easily maneuvered by just one person, reducing the amount of manual labor required.

Hand Trucks are perfect for various applications, including order picking, workstation and assembly cell replenishment, lean manufacturing, and other material handling requirements. Most modern hand trucks are built with ergonomics and safety in mind. When maneuvering the cart correctly, the warehouse staff can safely transport materials and stay free from injury.

Pallet Jacks or pallet trucks are cousins of dollies, hand trucks, and forklifts, designed with parallel forks so a single person can move pallets. They can feature a manual pump system similar to a car jack to lift the pallets, or they can have an electric lift system.

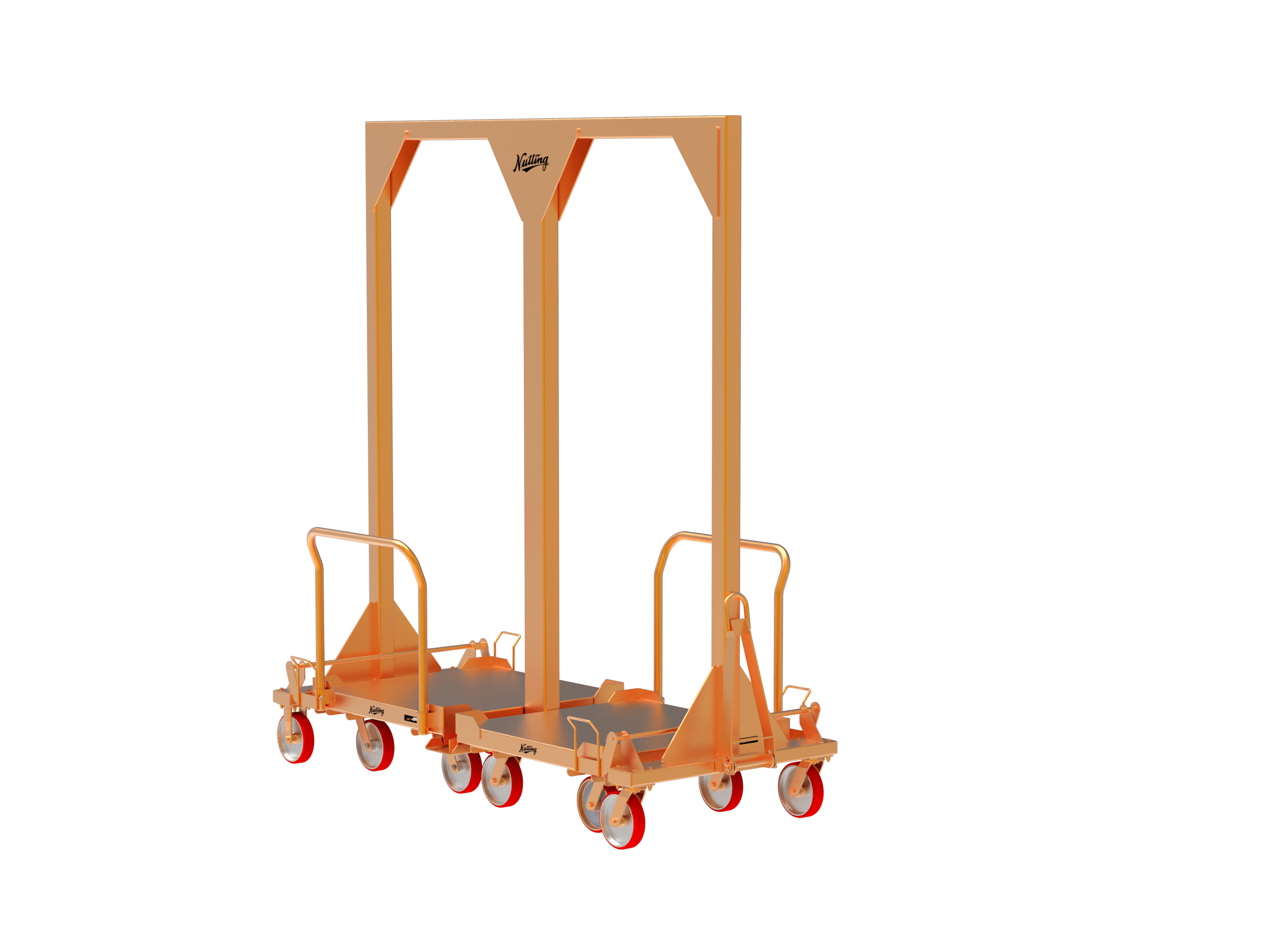

A-Frame Carts are designed to move large quantities of long, flat materials such as glass windows, door frames, partitions, and sheet stock and can be loaded from either side, offering versatility. In addition, they can carry heavier loads than a conventional hand truck or dolly, making them ideal for moving large, heavy objects such as metal security doors or sheets of plywood.

Machine Operated

This category will include all industrial trucks, such as forklifts and side loaders. While these machines require more space to maneuver, they can handle larger, heavier loads than a hand-operated cart.

Forklifts or lift trucks are a valuable staple of many warehouse settings. While they are primarily designed to load pallet racks, you can further increase the utility of forklifts by adding attachable trailers that can also be loaded with materials. This turns the forklift into a train engine of sorts.

Side Loaders are a type of forklift designed to pick up longer items or fit narrow aisles. As their name suggests, they can be loaded from several different directions as opposed to a standard forklift that must load directly in front.

Order Pickers are another type of lifting device, but in this case, they raise a platform to the various levels of a pallet rack so that a human order picker can load the platform with the needed materials.

Automated Material Handling Systems

Automated storage and retrieval systems are engineered systems that include Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) working with conveyor systems. Although robotic delivery systems speed up the material handling process, automated equipment often has special requirements for the system to function correctly. While ideal for high-volume order fulfillment distribution centers, they require custom storage racks and a computer management system. In addition, AGVs need flooring that meets specific flatness, levelness, and curvature standards.

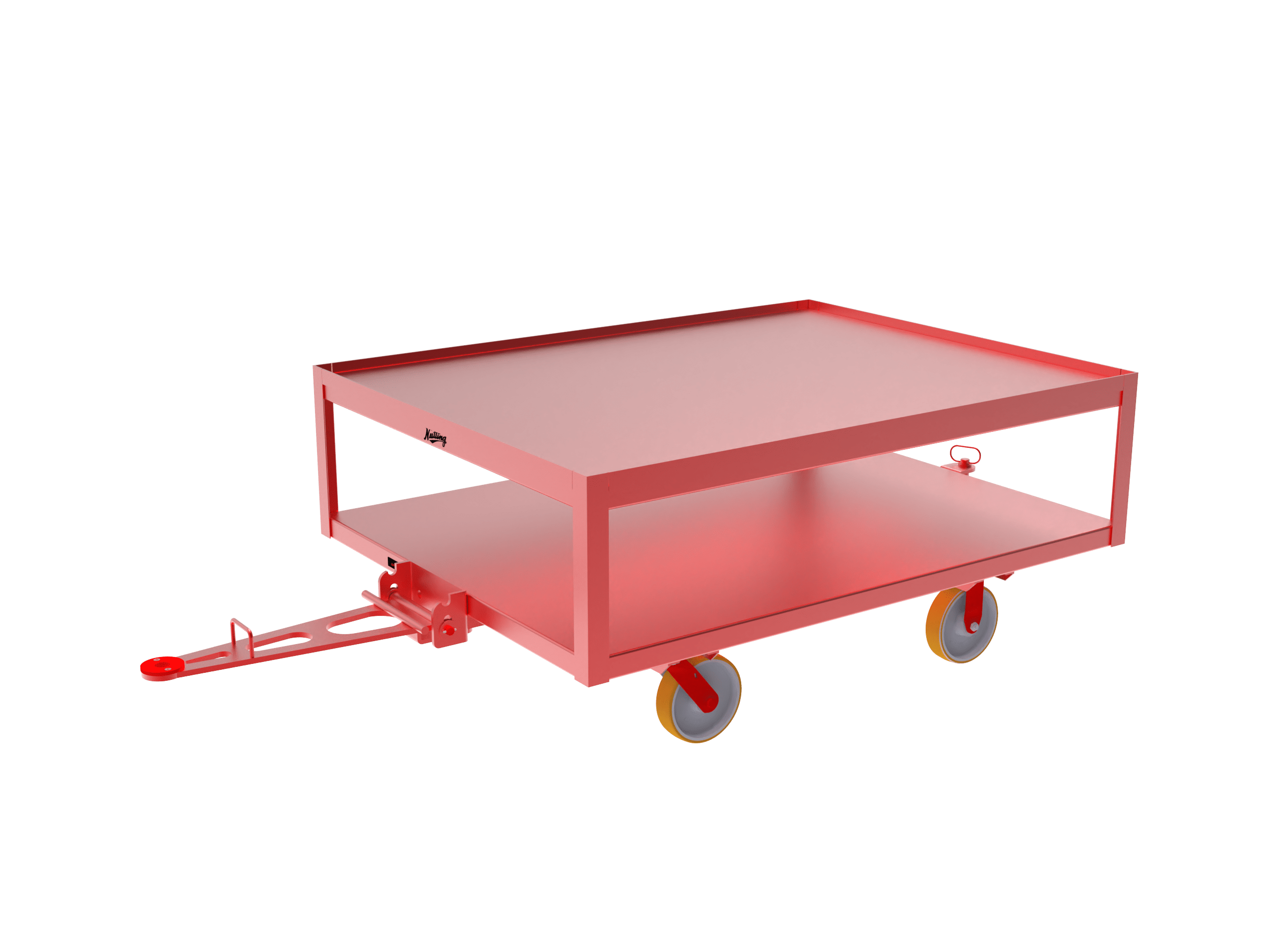

Choosing Warehouse Material Handling Equipment to Optimize Each Unit Load

Nutting Carts and Trailers takes the time to understand your specific warehouse operation to engineer and manufacture a product that meets those needs. Nutting has you covered whether you need a custom industrial cart or trailer with particular features or want a standard model with a few modifications. All our products are made in the USA using high-quality materials and components, backed by a comprehensive warranty, ensuring that you can count on them to perform reliably for years to come.