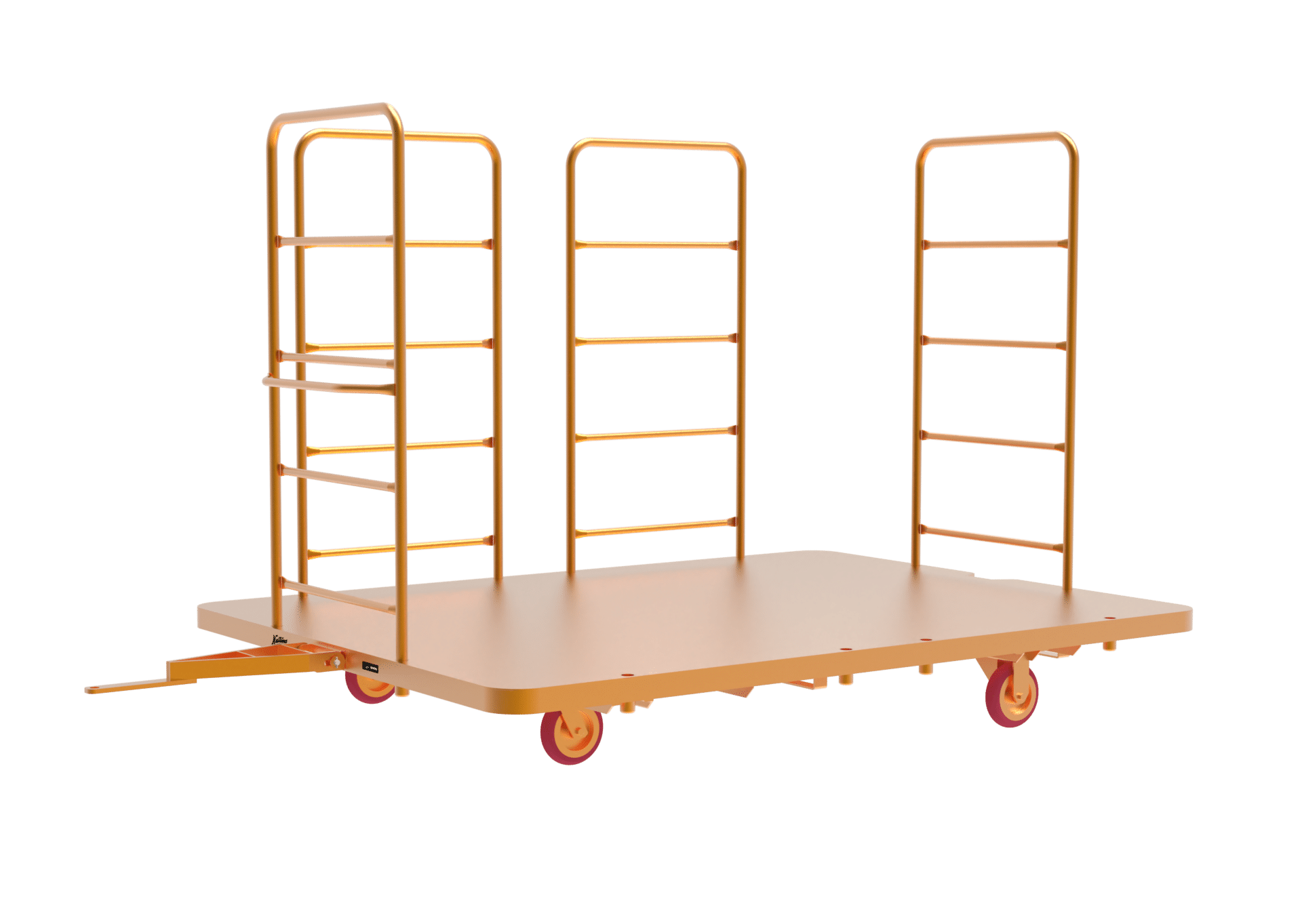

With industrial and heavy-duty equipment, the significance of the right tools cannot be overstated. This is where custom welded carts come into play, serving as essential tools tailored to meet the specific demands of various industries. In this comprehensive buyer’s guide, we delve into the benefits of custom welded carts and offer insights on designing and procuring the perfect cart for your business needs.

Benefits of Custom Welded Carts

Custom welded carts are renowned for their robustness and adaptability, making them a top choice for businesses across multiple sectors. Here’s a closer look at the advantages they offer:

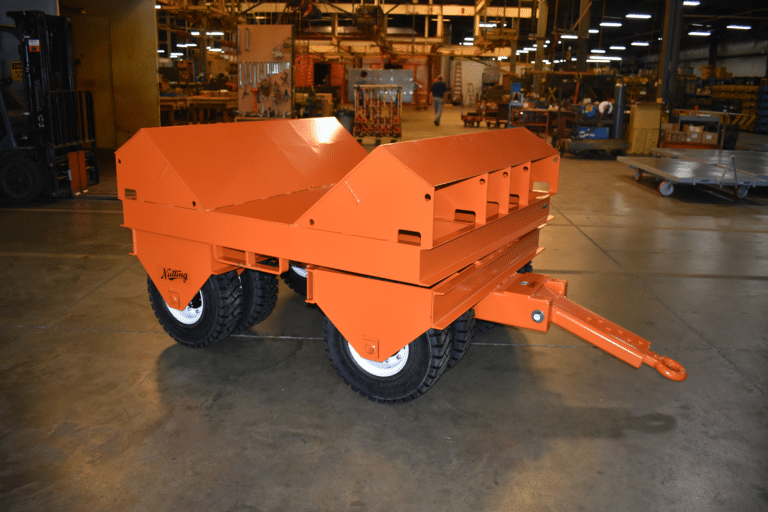

- Durability: Designed to endure, these carts can handle heavy loads and rugged terrain, making them a steadfast solution for industrial use.

- Versatility: Tailor a cart specifically for your operations, ensuring it performs a range of tasks efficiently.

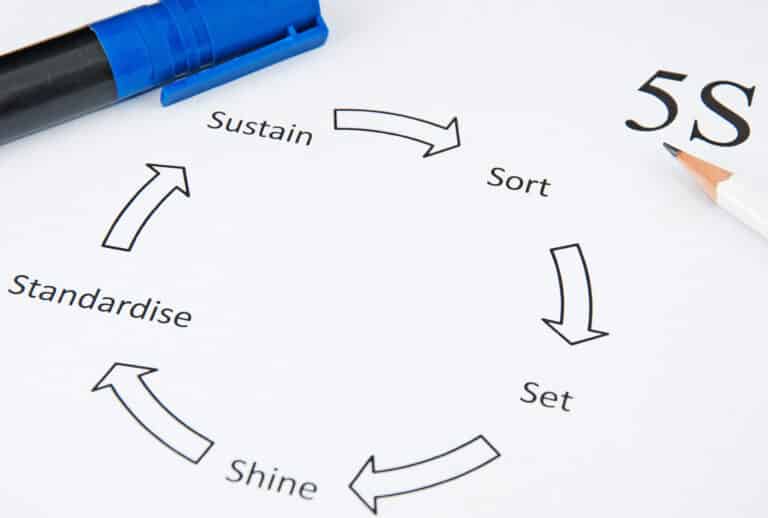

- Efficiency: A cart crafted to suit your particular requirements can significantly boost productivity and workflow in your operations.

- Safety: Opt for a cart that incorporates safety features, safeguarding both your workforce and equipment.

Designing Your Cart

To maximize the benefits of your custom welded cart, consider the following elements during the design phase:

Purpose

Identify the primary function of your cart. What tasks will it perform? What type of environment will it operate in? Will it need to support heavy loads? Answering these questions will help you define the optimal cart design, size, and features.

Materials

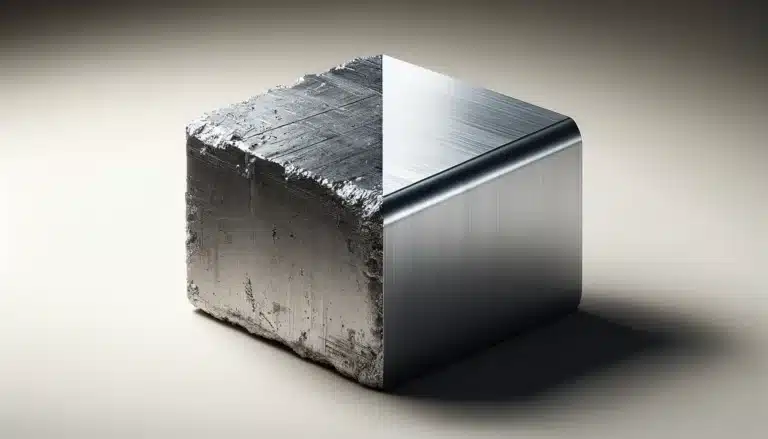

The choice of materials is crucial for the cart’s performance and durability. Steel is a common choice for its robustness and load-bearing capacity, ensuring a heavy duty cart. However, aluminum or stainless steel might be more appropriate for specific applications or environments due to their lighter weight and resistance to corrosion.

Features

The functionality of your custom welded cart can be enhanced with various features tailored to your needs:

- Wheels: Choose the right type and size based on the operating terrain. Cart heavy-duty wheels are essential for uneven surfaces, while smaller wheels might suffice for indoor applications.

- Handles: Design handles that facilitate easy maneuvering, whether for pushing or pulling.

- Shelves and compartments: Incorporate these for better organization and efficient transport of tools and materials.

- Brakes: For added safety and control, equip your cart with brakes.

Purchasing Your Custom Welded Cart

Selecting the right manufacturer is pivotal when it comes time to purchase your custom welded cart. Consider factors such as the manufacturer’s experience, reputation, and the quality of customer feedback. Maintaining clear and open communication with your manufacturer is crucial to ensure the final product meets your exact specifications.

By understanding the benefits and design considerations for custom welded carts, you can invest in a solution that enhances your business’s operational efficiency and safety. Custom carts are more than just equipment; they are a pivotal part of your workflow optimization.