Green warehousing reduces your carbon footprint and boosts efficiency with custom carts and energy-efficient solar power, saving costs and aiding the environment.

Warehouses and distribution centers are integral to the global supply chain, and their sustainability practices can have far-reaching impacts. Sustainable warehousing focuses on minimizing carbon emissions and reducing energy consumption within material handling and warehouse processes. In this article, we’ll explore how green warehousing practices, from energy-efficient equipment to renewable energy sources, are both eco-friendly choices and strategic business decisions that can transform your operations, benefit the environment, and enhance your bottom line.

The Rise of Green Warehousing in Supply Chain Management

In recent years, the logistics and supply chain sectors have witnessed a significant shift toward sustainable practices. A growing awareness of environmental issues is driving this change. Companies are also increasingly recognizing that integrating green strategies into warehouse operations is not just about environmental responsibility but also operational excellence.

Sustainable warehousing practices like adopting energy-efficient lighting, solar panels, and optimized material handling equipment contribute to substantial energy savings, leading to reduced costs and enhanced operational efficiency. By reducing energy consumption, warehouses can lower operational costs while minimizing environmental impact.

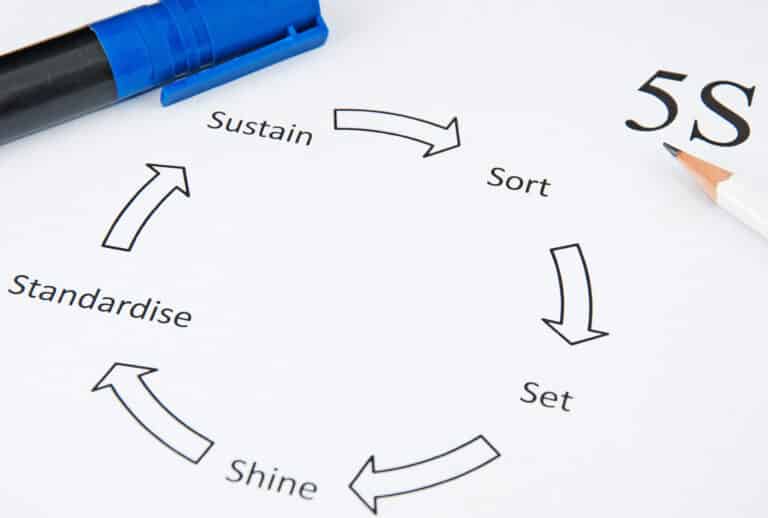

Implementing the 5S method in warehousing, a methodology focused on organizing and optimizing the workspace, complements green initiatives by creating a more streamlined, energy-conscious environment emphasizing waste management and reduction.

Together, these practices demonstrate how sustainable warehousing is becoming a more mainstream part of modern supply chain management, offering a dual benefit of ecological conservation and operational effectiveness.

Designing Eco-Friendly Warehouse Layouts

The design of a warehouse plays a decisive role in its environmental sustainability. Incorporating eco-friendly elements into the warehouse can dramatically improve your carbon footprint and operating costs. Here are just a few examples of this in action:

Skylights

- Environmental Impact: Reduces reliance on artificial lighting, lowering energy consumption.

- Economic Impact: Improved natural lighting may decrease energy costs and enhance employee productivity.

Green Building Materials (e.g., Recycled Steel, Sustainable Wood, Low-VOC Paints)

- Environmental Impact: Minimizes the carbon footprint and improves indoor air quality.

- Economic Impact: The right selection of materials can offer durability and less maintenance, leading to long-term cost savings.

Energy-Efficient Insulation

- Environmental Impact: Reduces the energy needed for heating and cooling, decreasing greenhouse gas emissions.

- Economic Impact: Lowers energy bills by maintaining a more consistent internal temperature.

Rainwater Harvesting Systems

- Environmental Impact: Reduces water consumption and the strain on municipal water supplies.

- Economic Impact: Cuts water utility costs and provides an alternative water source for non-potable uses like landscaping or cleaning.

Solar Panels

- Environmental Impact: Generates renewable energy, reducing dependence on fossil fuels.

- Economic Impact: Reduces electricity bills and can potentially generate income by selling excess energy back to the grid.

LED Lighting

- Environmental Impact: Consumes less energy and has a longer lifespan than traditional lighting.

- Economic Impact: Upgrading to LED lighting can reduce electricity costs and the frequency of bulb replacements.

Smart HVAC Systems

- Environmental Impact: Increases energy efficiency and reduces carbon emissions.

- Economic Impact: Lowers operational costs through more effective heating, ventilation, and air conditioning.

Eco-Friendly Flooring (e.g., Recycled Materials, Sustainable Wood)

- Environmental Impact: Reduces deforestation and the carbon footprint associated with flooring materials.

- Economic Impact: Often requires less maintenance and has a longer lifespan, reducing long-term costs.

By focusing on these sustainable design elements, you can make a positive environmental impact and enjoy economic benefits through energy savings, reduced maintenance costs, and improved operational efficiency.

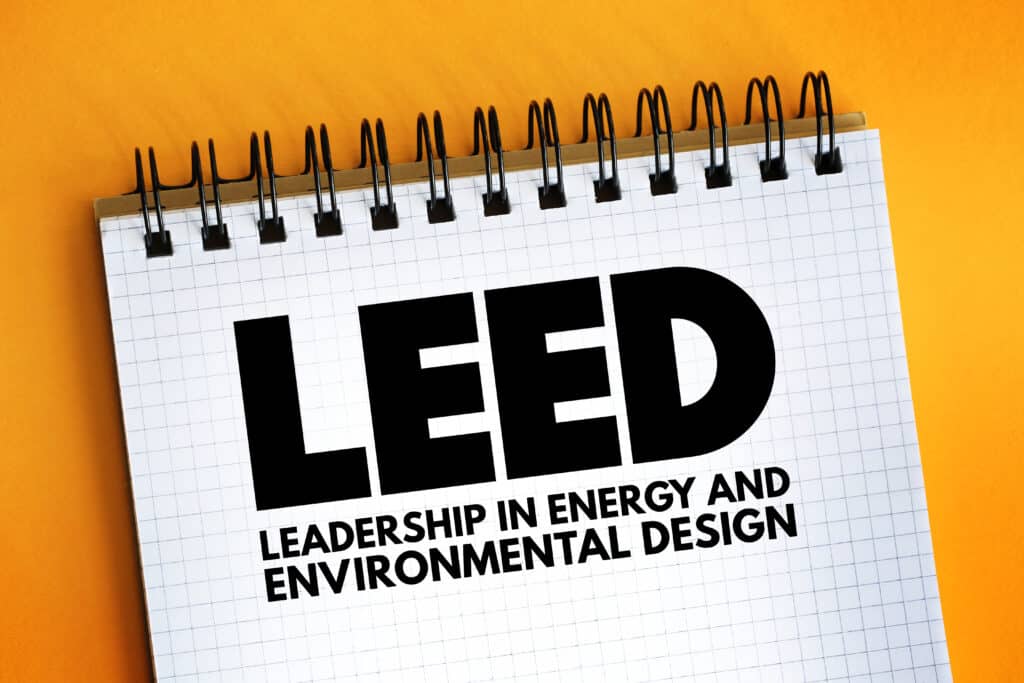

LEED Certification

Leadership in Energy and Environmental Design (LEED) certification provides a framework for understanding and implementing sustainable building practices. Warehouses achieving LEED certification meet high environmental standards for energy efficiency, water usage, and material selection.

By aiming for LEED certification, warehouse designers and operators commit to a higher standard of environmental responsibility. This benefits the planet and positions the organization as a leader in warehouse sustainability. Even though there are added expenses in obtaining this certification, LEED-certified warehouses often see reduced operational costs, enhanced marketability, and improved worker satisfaction due to healthier working conditions.

Energy-Efficient Forklifts, Carts, Tuggers, and Trailers

Your choice of material handling equipment can also significantly alter your warehouse’s carbon footprint. Energy-efficient equipment is specifically designed to lower energy consumption while boosting productivity. For example, energy-efficient forklifts significantly reduce emissions and energy use compared to conventional models.

Similarly, custom carts and trailers that are tailored for specific warehouse tasks and layouts can greatly enhance operational efficiency. These optimizations mean less equipment is needed, reducing energy consumption. Electric tuggers are also an excellent alternative to traditional material handling vehicles, offering a quieter, more energy-efficient solution that reduces emissions while still providing the necessary power and maneuverability for moving pallets within the warehouse.

Efficient Storage Systems and Logistics Management

Incorporating efficient storage systems is another key strategy in promoting sustainability in inventory management. Utilizing vertical storage solutions and compact shelving units maximizes warehouse space and reduces the footprint of storage areas. This reduces the energy required for heating, cooling, and lighting large storage spaces.

Logistics management also plays a key role in sustainable inventory practices. By streamlining the logistics process, warehouses can minimize unnecessary handling and movement of goods, reducing energy consumption and lowering emissions. Advanced logistics management tools can optimize routes for transportation and delivery, further contributing to reduced carbon emissions and enhanced operational efficiency.

Reducing Emissions with Automation

Integrating automation and robotics in warehouse operations can positively impact sustainability. Automated systems and robotic solutions streamline various warehouse processes, from inventory management to order picking, reducing the reliance on manual, energy-intensive tasks and equipment, thereby decreasing the overall energy consumption and associated emissions.

Warehouse Management Systems (WMS) for Enhancing Efficiency

WMS can optimize operations by providing real-time data and analytics, enabling warehouses to make more informed energy use and inventory management decisions. This can lead to significant reductions in energy consumption, as WMSs help organize warehouse layouts efficiently, reduce the distance forklifts and other equipment need to travel and streamline the picking process.

WMS can also help schedule equipment usage and maintenance, ensuring that machinery runs at peak efficiency and does not consume unnecessary energy. This not only contributes to lower operational costs but also aids in reducing the overall energy footprint of warehouse operations.

Are you ready to make your warehouse operations more sustainable and efficient? Nutting Material Handling Solutions offers custom carts, electric tuggers, and trailers designed to reduce your carbon footprint and boost productivity. Contact us today to learn how we can support your sustainability initiatives with our material handling solutions. Let’s work together to create a more sustainable logistics industry.

Inspired by Our Solutions? Let's Talk!