Explore the different types of material handling equipment, from storage solutions to advanced robotics, enhancing efficiency in warehousing.

There are many types of material handling equipment in the warehousing industry. From storage solutions to advanced robotics, each piece has a specific purpose that can improve efficiency in the supply chain. Picking the right equipment for your needs is important, as the right choice can make your operations safer, more productive, and more efficient. This guide will help you understand the roles of standard equipment, like forklifts for lifting heavy materials and conveyor systems for assembly lines. With a solid understanding of the equipment, you’ll make more informed decisions for your facility. Dive in to find out more about how to enhance your warehouse operations.

The Backbone of Modern Warehouses: Understanding Material Handling Equipment

From the most basic baskets employed by hunter-gatherer societies to sophisticated automated storage and retrieval systems, the evolution of material handling is part of what makes human society function. As civilization advanced, the need for more complex supply chains and warehousing drove the creation of new equipment to handle those new demands. While there is still a place for hand-operated tools, the pace and volume at which we need to move heavy objects have ushered in an era where autonomous forklifts, robotic delivery mechanisms, and various advanced equipment are commonplace in modern warehouses.

Choosing the right material handling equipment is crucial for maximizing floor space and optimizing workflow.

We have four broad categories for material handling equipment:

- Storage Equipment: This includes pallet racks and mezzanines that help organize and store goods.

- Engineered Systems: Integrating elements like automated guided vehicles and conveyor belts, engineered systems ensure products are moved efficiently and accurately across the facility.

- Industrial Trucks and Trailers: Comprising a variety of vehicles like pallet trucks, walkie stackers, and ever-reliable forklifts, industrial trucks, and trailers are indispensable for navigating and transporting materials in a warehouse environment.

- Bulk Material Handling: Devices like hoppers and bucket elevators are essential for managing and moving large quantities of materials.

Understanding and differentiating between these categories is fundamental for ensuring streamlined operations and fully harnessing the potential of a warehousing setup.

Storage Equipment: More Than Just Shelving

Advanced warehousing environments have expanded storage solutions beyond basic shelving. These equipment pieces play critical roles:

- Mezzanines: These are elevated platforms that create additional storage areas without expanding the physical size of the warehouse.

- Pallet Racks: These are frameworks specifically engineered to hold and organize palletized items to minimize the storage footprint.

- Silos: Typically found in agricultural settings, silos are structures that store large amounts of materials like grains.

- Drive-in Racks: These racks help maximize space optimization. They allow forklifts to enter directly into the lanes of stacked goods.

- Cantilever Racks: These are specialized racks with protruding arms, perfect for storing elongated or irregularly shaped items.

Harrington Hoists: A Key Player in Warehouse Equipment

In the diverse landscape of material handling equipment, Harrington Hoists stands out with its range of robust and efficient hoisting solutions. These hoists are integral to enhancing the operational efficiency of warehouses and industrial facilities.

Manual Hoists: Harrington offers a variety of manual hoists, including lever hoists, which are essential for a wide range of lifting tasks. These hoists are known for their reliability and ease of use in various industrial scenarios.

Electric Hoists: The NER/ER Electric Hoist series, particularly the 3 Phase models, are built for heavy industrial use. These electric chain hoists are designed to handle rigorous demands and are a staple in environments where heavy lifting is routine.

Air Hoists: The TCR Air Chain Hoists are air-powered with a 100% duty rating, making them suitable for continuous operation. These hoists are appreciated for their fine feathering controls, which allow precise handling of loads, a critical feature in delicate operations.

Wire Rope Hoists: The RY Wire Rope Trolley Hoists are designed for spaces where low headroom is a challenge. They come with VFD controls for precise lifting and lowering, offering unparalleled accuracy in material handling.

Incorporating these varied types of hoists from Harrington into a warehouse’s material handling arsenal can significantly enhance the efficiency and safety of operations. The diversity in their offerings ensures that there is a Harrington hoist suitable for almost any material handling need in a warehouse environment.

Engineered Systems: Robotics and Beyond

The modern warehousing landscape heavily relies on advanced engineered systems. Some of the pivotal components of engineered material handling systems include:

- Conveyor Systems: Mechanized and automated conveyor belts move goods smoothly across different parts of a warehouse or facility.

- Sortation Systems: Automated systems designed to quickly and efficiently sort items based on specified criteria, such as size, weight, or destination.

- Carousel Systems: Rotating shelves or bins that bring items to the operator, often used in parts storage or small item picking.

- Robotic Delivery Systems: Advanced robots, driven by intricate algorithms, handle tasks like picking, sorting, and delivering items.

By integrating these systems, warehouses can improve their operations from mere storage facilities to ultra-efficient logistics hubs.

Automated Storage and Retrieval Systems (AS/RS)

Automated storage and retrieval systems are pivotal for enhancing warehouse efficiency:

- Computer-Controlled: These systems automatically place and retrieve loads from designated storage locations.

- Economic Efficiency: By automating processes, they help in:

- Reducing Labor Costs: Fewer manual processes mean fewer labor hours.

- Increasing Storage Density: These systems assist in maximizing space utilization.

- Speeding Up Inventory Turnover: Automated systems ensure quicker access and replacement of inventory.

- Minimized Human Error: The reliance on technology provides smoother operations and improved inventory management.

Industrial Carts and Trailers: The Backbone of Material Movement

Warehouses aren’t merely storage hubs. Their efficiency hinges on the seamless movement of materials. Industrial carts and trailers allow for transporting items swiftly, safely, and efficiently.

Basics of Industrial Carts and Trailers

Traditionally, hand-operated trucks formed the foundation of material movement in warehouses and industrial settings. As technology evolved, so did these trucks, leading to the integration of mechanized and partially mechanized features. However, these essential tools, regardless of their advancement, remain fundamental in the world of material handling, including:

- Hand Trucks: A common sight in many warehouses, they empower workers to lift and transport loads effortlessly.

- Pallet Jacks: These tools, available in manual or electric assist formats, are essential for lifting and shuttling pallets throughout a warehouse.

- Dollies: With a four-wheel design and platform, they’re adept at moving heftier items.

- Platform Trucks: Their flatbed design makes them the go-to for transporting bulk items.

- Tugger Carts and Trailers: Specifically crafted for navigating tight spaces, these versatile tools can either be hand-operated or connected to lift trucks or tuggers. They excel at ensuring the efficient movement of materials, even in challenging environments.

- Order Pickers: These industrial trucks enable workers to ergonomically fetch items from varied shelf heights.

Advanced Industrial Carts and Trailers

With evolving demands, the warehouse industry has seen the emergence of more specialized and advanced industrial trucks:

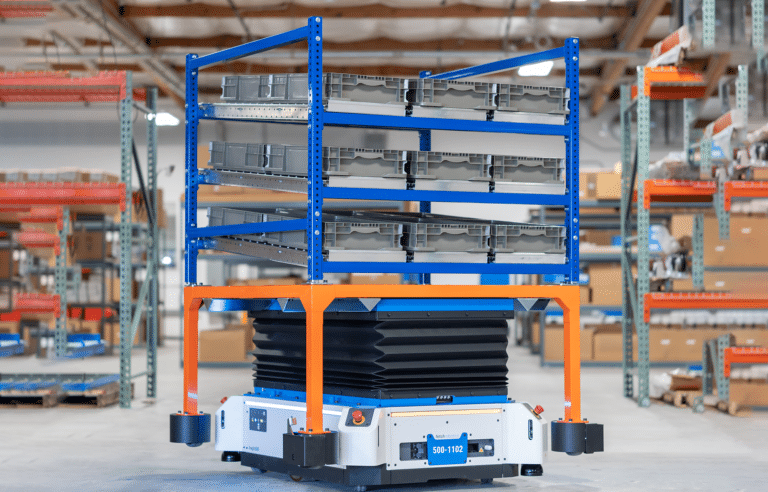

- Automated Guided Vehicles (AGVs): These automatic guided vehicles, which can be part of an Automated Storage and Retrieval System, employ sensors to follow set paths, drastically cutting down on manual input.

- Side Loaders: These are invaluable in tight quarters, adeptly lifting loads from the side for meticulous material handling.

- Lift Truck: A versatile tool for hoisting and transporting heavier loads within the facility.

- Mobile Robots: These robots autonomously transport materials using advanced algorithms and sensors.

- Tugger Trains: These devices make transporting multiple loads across the warehouse safer and more efficient.

- Ride-On Tugger: The ride-on tugger is great for large warehouse spaces and facilities. Operators can physically ride and control the traditional manual versions, ensuring swift transport over extended distances and minimizing fatigue. There are also partially and fully automated ride-on tuggers. These self-navigating devices, which can be pre-programmed or operated using sensors and algorithms, offer an added layer of efficiency by transporting loads without human intervention.

- Electric Assist Hand Tugger: These compact tuggers are perfect for tighter spaces with narrow aisles or scenarios demanding more precision. Despite their smaller stature, they deliver substantial power, enabling operators to handle loads smoothly in constrained areas or along intricate pathways. The electric assist functionality further eases the transport process, reducing the strain on operators.

- Ride-On Tugger: The ride-on tugger is great for large warehouse spaces and facilities. Operators can physically ride and control the traditional manual versions, ensuring swift transport over extended distances and minimizing fatigue. There are also partially and fully automated ride-on tuggers. These self-navigating devices, which can be pre-programmed or operated using sensors and algorithms, offer an added layer of efficiency by transporting loads without human intervention.

- Electric Assist Hand Tugger: These compact tuggers are perfect for tighter spaces with narrow aisles or scenarios demanding more precision. Despite their smaller stature, they deliver substantial power, enabling operators to handle loads smoothly in constrained areas or along intricate pathways. The electric assist functionality further eases the transport process, reducing the strain on operators.

These trucks and trailers ensure that warehouses function with peak efficiency. From moving products within the warehouse to loading and unloading shipments, industrial trucks remain a crucial component of the supply chain.

Bulk Material Handling: Catering to Heavy Loads

When managing large quantities of raw materials or bulk items, standard equipment might need help handling the workload. Bulk material handling equipment caters to transporting heavy loads, ensuring efficiency and safety.

Essential Equipment for Bulk Handling

- Bucket Elevators: Handling tasks like lifting bulk seeds to stacked storage, these elevators are helpful tools for efficient vertical transportation.

- Hoppers: While they excel in storing materials, their funnel-like design also assists in the smooth input and regulated output of items like pellets.

- Conveyor Belts: An essential in many warehouses, conveyor belts streamline the movement of goods from one point to another, reducing manual handling and increasing efficiency.

- Grain Legs and Grain Elevators: While primarily associated with agricultural settings, these tools are integral for practical storage and transport in some specialized warehouses handling grains or similar materials.

- Silos: While they stand out for their capacity to house vast quantities of bulk items, their design also simplifies and regulates material distribution.

- Stackers: Devices that help organize bulk materials into orderly piles or stacks, maximizing storage space.

- Reclaimers: These devices are usually used in conjunction with stackers. They recover bulk materials from stockpiles, ensuring efficient use of stored materials like coal or minerals.

- Front-End Loaders: Often associated with construction, these machines can also be a piece of vital warehouse equipment for quickly moving substantial amounts of materials.

Effective bulk material handling is about more than just equipment. Proper workflow, strategic storage planning, and continuous optimization are crucial. By integrating the right tools with efficient processes, warehouses can ensure smooth operations regardless of the scale.

Navigating the Material Handling Landscape with Expertise

From forklifts designed for heavy lifting to sophisticated conveyor systems that streamline supply chains, understanding the nuances of each type of material handling equipment is necessary to make informed decisions that impact your immediate operations and influence the long-term efficiency and safety of a warehousing setup.

Whether you’re a seasoned warehouse manager or just starting your career in material handling, leaning on Nutting’s expertise can help you find the right equipment for your facility. Ready to take your warehousing to the next level? Explore Nutting’s range of tailored industrial cart solutions to find the perfect fit for your needs.